Screen printing isn’t just about screens and ink, there are a few essential side tools that make your prints cleaner, sharper, and longer-lasting. Whether you’re a beginner building your first setup or leveling up your studio, these tools help you prep, coat, clean, and reuse your screens like a pro

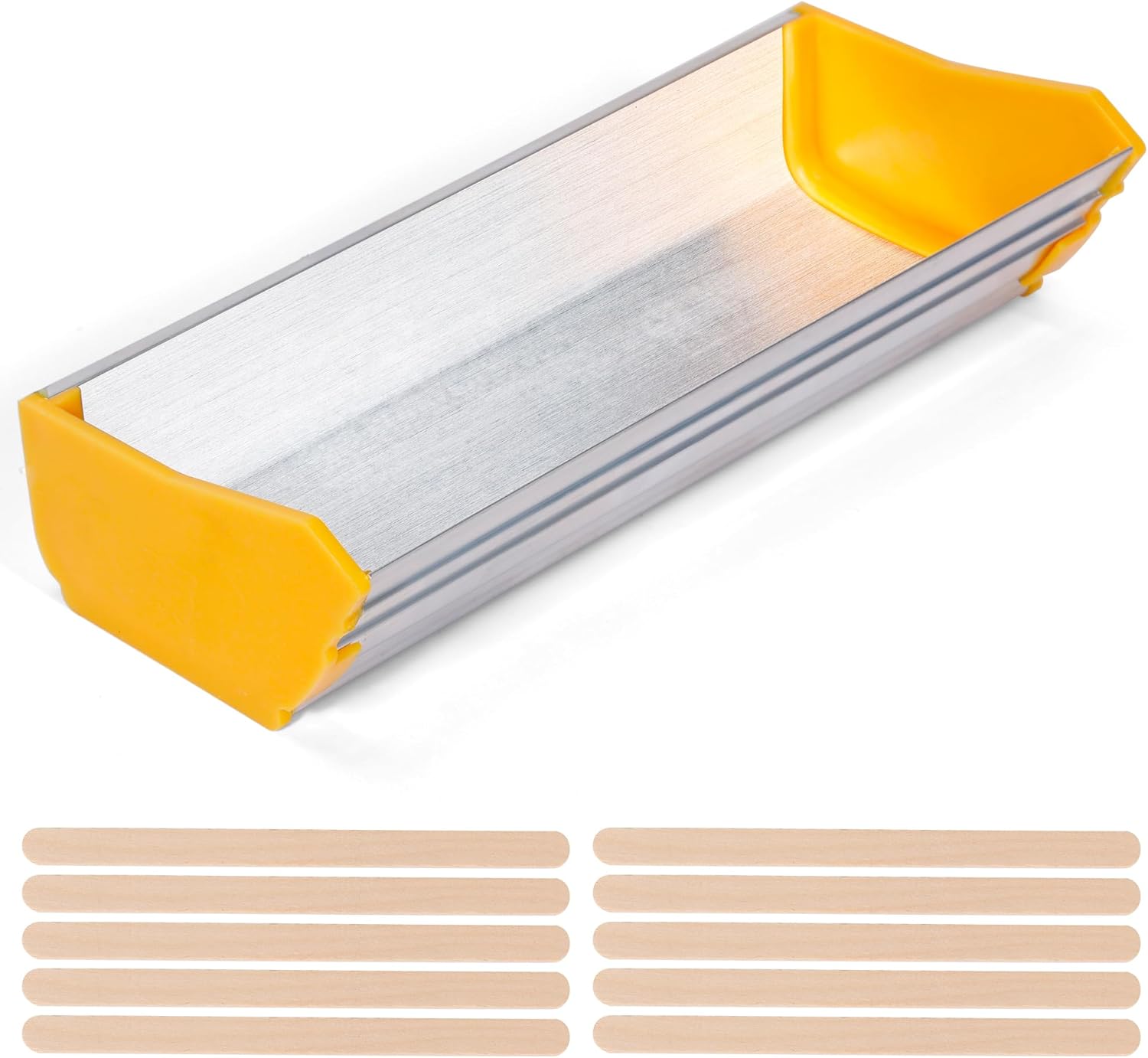

Scoop Coater

A scoop coater is a metal trough used to apply emulsion evenly across your screen.

It helps you control the thickness and smoothness of the emulsion layer, which directly affects how crisp your stencil will be.

- How to use it: Fill the coater with emulsion, hold it at a slight angle, and glide it smoothly up the mesh.

- Tip: Always coat both sides (print side last) for best exposure results.

- Why it matters: Uneven coating can lead to pinholes, fuzzy lines, or overexposed designs.

3 Pcs Dual Edge Aluminum Emulsion Scoop Coater

for Silk Screen Printing Coating Tool 8” 10” 16”, Screen Printing Supplies, 3 Sizes

$24.99

Zonon Dual Edge Aluminum Emulsion Scoop Coater

for Silk Screen Printing Coating Tool(3 Pcs,8inch,10inch,16inch)

$22.49

Caydo Dual Edge Emulsion Scoop Coater

with 10 PCS Wooden Stirring Sticks, 6 Inch Aluminum Silk Screen Printing Coating Tool for Silk Screen Printing

$9.99

Squeegee

The squeegee pushes ink through the stencil onto the fabric. It’s one of the most important tools in screen printing.

Tip: Keep your squeegee edges clean and sharp, dull edges can ruin detail and waste ink.

Different blades:

- Soft (60 durometer): good for thicker ink layers or textured prints.

- Medium (70 durometer): a great all-around option for t-shirts.

- Hard (80 durometer): ideal for fine details and thin inks.

Caydo 2 Pieces 2 Sizes Screen Printing Squeegee

75 Durometer Wooden Ink Scraper for Screen Printing, 9.4 and 5.9 inch

$9.99

Caydo 3 Pieces 3 Sizes Screen Printing Squeegee

75 Durometer Wooden Ink Scraper for Screen Printing Fabric, 5.9 Inch, 9.4 Inch and 13.7 Inch

$18.99

Degreaser

Before coating a screen with emulsion, you need to degrease it. Even tiny oil spots or dust can cause the emulsion to separate or bubble.

Why it matters: Clean screens = smoother emulsion coat and fewer stencil issues.

How to use it: Apply degreaser to both sides of the mesh, scrub gently, and rinse thoroughly with water. Let it air dry before coating.

Ecotex® Screen Printing Mesh Degreaser (Quart – 32oz.)

Silk Screen Cleaner, Oil and Residue Remover – Screen Printing Frame Degreaser and Mesh Cleaner, Eco-Friendly Screen Printing Supplies

$31.04

Tape

Screen printing tape is used to seal off the edges of your stencil and any open areas of mesh where you don’t want ink to pass through. It prevents leaks, keeps your print edges sharp, and makes cleanup easier. You can use special screen printing tape (made to resist both water-based and plastisol inks) or masking tape if you’re just starting out. Always tape around the inner frame edges and any unused parts of the screen before printing. After you finish, simply peel it off, it helps protect your emulsion and keeps your screens in good condition for longer.

SEBETOW Masking Tape Bulk 10 Packs

0.75 Inch – Masking Tapes Artist Drafting Tapes White Beige, General Purpose for Craft, Art, Office, School, 3/4 Inch x 55 Yards x 10 Rolls

$16.99

SWRT Masking Tape 0.75 Inch x 55 Yards

Pack of 4 Rolls, Adhesive Painting Tape Bulk for General Purpose Beige White Color, Paper Tape for Painting, Crafting, School Stationery, Arts, Home Use etc

$6.79